I was sniping from a tree recently and found that it was a pain to change mags. Anyway I had an idea. Why not get a manufacturer to make a High Capacity Mag for the VSR10. So it would be like an AEG mag but for the VSR10. This is what I had in mind:

Anyway after asking a couple of manufacturers to make it and both saying no, I then though that I might as well make my own High Capacity Mag from a SHS M4 P-mag

The reason I chose this mag is because it is made of plastic and so it can be filed to fit the VSR10 Mag well.

So here is a guide on how to make the VSR10 High Capacity mag.

1. Measure the depth of the VSR10 mag (about 26.5-28mm) and then mark it on your M4 mag. Tape around the mag so you know how deep the mag will fit into the VSR10 magwell

2. Sand each side so that it is the same width as a VSR mag (21.2mm wide). You want it to fit into the magwell as snug as possible.

When you try to push the mag in it will not go all the way in because inside the magwell is some plastic ribs that stick out. These ribs will be the thing that stops the mag from moving backwards

3. Next sand the front a lot so that the wall on the mag is only 1mm wide

4. Then grind the top of the m4 mag off where the bb's come out. This needs to be 100% flat. This will be replaced by a VSR10 mag top

5. Cut off the top of the VSR mag

6. Grind the top square of the VSR mag to be flat. Make sure that you do not grind any of the square block away as this is the exact height we need for the bb's to feed.

7. Pull all the internals out of the M4 mag as it is easier to do the rest of this modification without them in the mag. You will most likely also have to clean these parts from dust at the end of this guide too.

8. Unscrew the VSR10 square mag top so that it comes apart into 2 pieces.

9. Have the M4 mag internals in 2 pieces and align up one side with one half of the VSR square top and super glue it in place so that the bb's can feed up through the mag pipe and through the VSR10 mag ejection port. Be exact when doing this.

10. Once the glue is set, screw both halves of the VSR10 mag tops together. Put super glue on the other half of the VSR10 square top and then put both halves of the M4 mag together. Make sure that the glue sticks well to the M4 mag. (Note: You do not want the 2 halves of the M4 mags or the VSR square tops to stick together as you may want to pull it apart one day. So be careful and do not use too much glue)

11. Then put all the internals back in and screw it all back together. Make sure that you also put the part of the VSR mag top that stops bb's from flying out. It has a couple of little springs that you need to put in place too

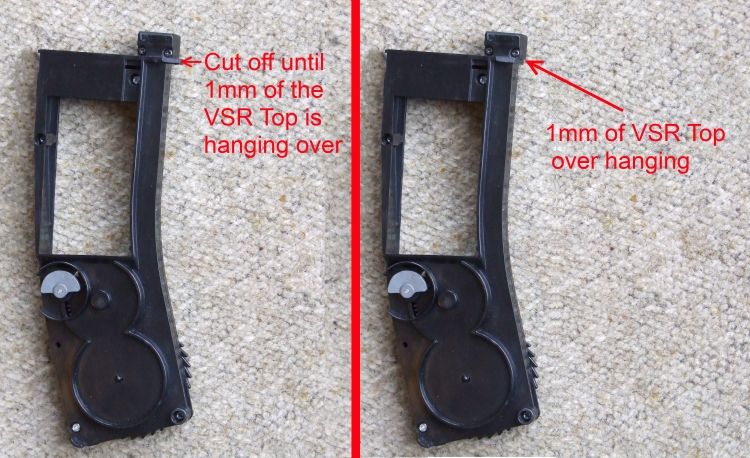

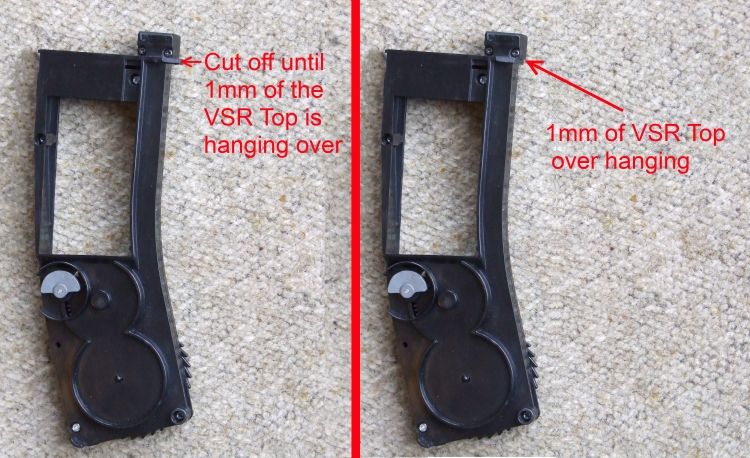

12. Next you need to make the VSR Square Top overhang by 1mm. This is so when you put together the internals with the outer mag the VSR top should be flush with the outside front face of the m4 mag. To make the VSR Top over hang by 1mm you just need to cut the m4 mag internal housing a little. Here is some pictures of how to cut it:

13. Now just add some adhesive foam to the back of the mag internals. This will push the top of mag internals forward when they are in the outer housing so that the VSR top is flush with the front face of the M4 mag casing.

14. Now put some foam in the outer mag casing at the bottom on the inside. This will move the bottom of the internals forward a little. (Note: You may not have to do this step. I did it because I wanted everything to be very snug).

15. Put the internals and the external housing back together.

16. Now you need to cut some slots into the side of the mag so that the magwell ribs fit perfectly into the slots. These slots need to be cut in the perfect position. So take the stock apart and put the mag in as far as it will go and then mark where to cut the slots. (Note: It is better to have the slots a little further back and if you find the mag will not go into the stock then you can cut the slots further forward. If the slots are too far forward then the mag may fall out.)

17. Cut the slots into the mag about 1.5mm deep

Once you have the slots on the side of your mag put the gun back together and make sure the mag pushes all the way in. It won't lock in place until you have finished the next step but is should not move backwards and there should be no wobble at all. The more snug the better.

18. Now cut a hole in the front of the mag (this is the catch hole that keeps the mag from falling out). Measure 28mm from the top of the VSR square down the front of the mag. This is the very top of the hole where the mag release will catch onto. Make the hole the same size as the hole in your current mag. So 10mm (wide) x 3.5mm. If the mag does not catch onto the mag catch when you put it in the magwell, just cut a little bit more off the hole. So that it is 27.8mm from the top of the VSR Square. Only cut really small amounts. The more snug the better. If it is not snug then the mag will fall out easily.

19. Done. Hay presto. I now have a 330 round high Cappa VSR10 mag

If done right the mag will fit really snug and firm. This mod rocks!!!!!!

Anyway after asking a couple of manufacturers to make it and both saying no, I then though that I might as well make my own High Capacity Mag from a SHS M4 P-mag

The reason I chose this mag is because it is made of plastic and so it can be filed to fit the VSR10 Mag well.

So here is a guide on how to make the VSR10 High Capacity mag.

1. Measure the depth of the VSR10 mag (about 26.5-28mm) and then mark it on your M4 mag. Tape around the mag so you know how deep the mag will fit into the VSR10 magwell

2. Sand each side so that it is the same width as a VSR mag (21.2mm wide). You want it to fit into the magwell as snug as possible.

When you try to push the mag in it will not go all the way in because inside the magwell is some plastic ribs that stick out. These ribs will be the thing that stops the mag from moving backwards

3. Next sand the front a lot so that the wall on the mag is only 1mm wide

4. Then grind the top of the m4 mag off where the bb's come out. This needs to be 100% flat. This will be replaced by a VSR10 mag top

5. Cut off the top of the VSR mag

6. Grind the top square of the VSR mag to be flat. Make sure that you do not grind any of the square block away as this is the exact height we need for the bb's to feed.

7. Pull all the internals out of the M4 mag as it is easier to do the rest of this modification without them in the mag. You will most likely also have to clean these parts from dust at the end of this guide too.

8. Unscrew the VSR10 square mag top so that it comes apart into 2 pieces.

9. Have the M4 mag internals in 2 pieces and align up one side with one half of the VSR square top and super glue it in place so that the bb's can feed up through the mag pipe and through the VSR10 mag ejection port. Be exact when doing this.

10. Once the glue is set, screw both halves of the VSR10 mag tops together. Put super glue on the other half of the VSR10 square top and then put both halves of the M4 mag together. Make sure that the glue sticks well to the M4 mag. (Note: You do not want the 2 halves of the M4 mags or the VSR square tops to stick together as you may want to pull it apart one day. So be careful and do not use too much glue)

11. Then put all the internals back in and screw it all back together. Make sure that you also put the part of the VSR mag top that stops bb's from flying out. It has a couple of little springs that you need to put in place too

12. Next you need to make the VSR Square Top overhang by 1mm. This is so when you put together the internals with the outer mag the VSR top should be flush with the outside front face of the m4 mag. To make the VSR Top over hang by 1mm you just need to cut the m4 mag internal housing a little. Here is some pictures of how to cut it:

13. Now just add some adhesive foam to the back of the mag internals. This will push the top of mag internals forward when they are in the outer housing so that the VSR top is flush with the front face of the M4 mag casing.

14. Now put some foam in the outer mag casing at the bottom on the inside. This will move the bottom of the internals forward a little. (Note: You may not have to do this step. I did it because I wanted everything to be very snug).

15. Put the internals and the external housing back together.

16. Now you need to cut some slots into the side of the mag so that the magwell ribs fit perfectly into the slots. These slots need to be cut in the perfect position. So take the stock apart and put the mag in as far as it will go and then mark where to cut the slots. (Note: It is better to have the slots a little further back and if you find the mag will not go into the stock then you can cut the slots further forward. If the slots are too far forward then the mag may fall out.)

17. Cut the slots into the mag about 1.5mm deep

Once you have the slots on the side of your mag put the gun back together and make sure the mag pushes all the way in. It won't lock in place until you have finished the next step but is should not move backwards and there should be no wobble at all. The more snug the better.

18. Now cut a hole in the front of the mag (this is the catch hole that keeps the mag from falling out). Measure 28mm from the top of the VSR square down the front of the mag. This is the very top of the hole where the mag release will catch onto. Make the hole the same size as the hole in your current mag. So 10mm (wide) x 3.5mm. If the mag does not catch onto the mag catch when you put it in the magwell, just cut a little bit more off the hole. So that it is 27.8mm from the top of the VSR Square. Only cut really small amounts. The more snug the better. If it is not snug then the mag will fall out easily.

19. Done. Hay presto. I now have a 330 round high Cappa VSR10 mag

If done right the mag will fit really snug and firm. This mod rocks!!!!!!