Ok so let's start with the front and work your way back.

If they haven't changed the dimensions of the V2.5 gearbox cylinder this should be accurate. Getting all my ratios for the calculation from

AirsoftTech.dk - Calculator to calculate, Speed, Rate of Fire, Gearsets, etc. and all of my measurements from my own CA M110 that's about 4 years old now.

To maximize the closest barrel air volume ratio you will want a 6.01 tight bore 650mm inner barrel, which means putting that massive suppressor on the end. The only make I know of that is that big is Mad Bull. I know Fox Airsoft has some in stock (just came from the store)

R Hop the window as soon as you have that barrel. Amped Airsoft has laser cut patches if you aren't savy enough to do that or you can follow this S hop guide for a really cheap and effective R hop replacement.

I am not sure how tech savvy you are but I use the S hops and I love them.

Bucking should be a Mad Bull blue bucking that you have cut to flat hop, or if you are lazy get a Modify black flat hop bucking. The blue gets the better air seal but the black is less work for marginally less performance.

Hop up unit I always select for V2 configurations is the Maxx rotary hop up. Comes with its own R hop curved nub for maximizing that R hop you put in and its fine tuning let's you really dial in the shots.

Now the tough stuff.

The nozzle head has changed since I bought mine over 4 years ago so I'm not sure what size to get. It needs to have its own O ring so I personally go with the Maxx nozzle.

The cylinder head is going to be fractions of a mm bigger than the stock one so you will want a double O ring on it. I again turn to Maxx as they have great quality to their parts and they make some seriously tough stuff so you can abuse it a little. Alternatively SHS makes a piston head that is slightly bigger for a snug fit on V2s but better for the V2.5, it is just made differently and supposedly not as durable, but I have yet to break a cylinder head ever so you are the judge here.

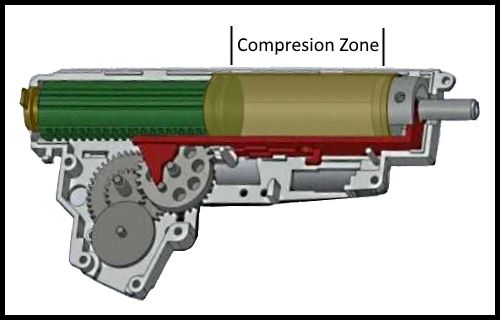

The piston head is up next and you want something with a little weight to it. Without going into it too much: more weight on the piston = better energy transfer to the bb. This will result in a little bit more noise however so it's going to depend on if you want a quiet system or an efficient one. SHS makes a "silent" piston head but it is more weight than anything so it will probably be louder, as will a Maxx piston head, but they have the weight advantage on their side. Lonex makes a lighter piston head with a concave surface that will actually deaden the sound from the air coming from the gearbox, and it will lower your cylinder volume slightly making that perfect air ratio for the barrel that much easier to achieve.

On to pistons. This needs to have a bit more weight to it so it will need to be aluminum and due to the nature of the V2.5 gearbox you need it to have the full 19 teeth. SHS is the only company I know of that makes a full 19 tooth aluminum piston. It will also need a full steel rack because of the hefty spring you will need to push all of this around, polycarbonate will just strip faster.

So the weight of the piston and piston head should correlate to the weight of bb you plan on shooting. Your milage may vary based on the field you plan on running it at but I have found that roughly somewhere between 20 and 25 grams is the best for mid range weights like .32 to .40 and 25 to 30 grams for over a .40. This is for standard DMR limits of 2J.

Spring is going to be whatever high quality tapered spring you find that will be able to meet your desired muzzle velocity. I tend to get ASG springs but thats just because that's what is at my local shop.

I dont remember offhand if the CA Isa quick change spring system, but I'm almost positive it isn't. If that is the case you will need a spring guide that has ball bearing guides on it. I recommend Lonex because it is great and should last a long while. If it is quick change you will need to see what fits the gearbox tolerance and find them with ball bearing guides on them, I know of none off the top of my head.

Gears and motor always work together. You NEED full steel gears. This will be a fail point if you do not get the gears that are tough enough and this honestly could be your biggest investment. SHS is again the go to brand for this but it needs a 19 tooth sector or you will not get the full performance of the V2.5 gearbox. Now you need to select the ratio, mixing torque gears and torque motor is a bad idea given it will pull anything, but be very slow, and mixing fast and fast will be like having a Ferrari try to pull a trailer in 7th gear, it may get there but it will take time and a lot of wasted energy. Pick either the ASG infinity 30k or 22k motors, the 30k being faster and the 22k having more torque, and pair it with a 16:1 gear ratio 19 tooth set. Pick the 22k for less trigger response but a heavier spring, or pick the 30k motor with a less heavy spring and better trigger response.

Make sure you shim this exceptionally well because that is what will keep the noise from the gearbox to a minimum. Everyone shims differently so I cant really tell you how to do it right, but I follow the Airsoft Tech on YouTube every time I shim a gearbox and it has done me well so far. Also make sure to radius that gearbox because CA never does and it's the fastest way to just break the entire thing dealing with that super heavy spring.

I am making a lot of inferences to your build here as well and without actually having it in my hands to see what's going on I can only guess. Make adjustments to your tolerances where needed if they made changes to the gearbox since I have owned mine, such as 18 instead of 19 tooth piston and sector gear if they shortened the gearbox at all.

Man that was a bit of an essay.